protected trademark by

PRAIMGEST S.A, 68 AVENUE DE LA LIBERTE, 1930 LUXEMBOURG

MUNICIPAL SLUDGE PROCESSING TECHNOLOGY

Technology approved by the European Agency for Competitiveness and Innovation (EACI) for the processing of biodegradable sludge from municipal wastewater treatment plants into building composites.

The sludge processing product is a new inert and stable product for use mainly in construction.

Treatment process of river sediments by mineralization, in which sludges from rivers are processed primarily by a recycling process and secondarily by a process of mixing primarily processed waste with a biological preparation made on the basis of enzymes and microorganisms.

The product is a material that can be used mainly as a top layer or. cover for the implementation of remediation of degraded areas.

RIVER SEDIMENT PROCESSING TECHNOLOGY

RDF / SRF PROCESSING TECHNOLOGY

Waste plastic is one of the major ecological problem of modern society, so it is important that we always find new and better ways of material processing, possibly mass recycling into new products.

Our technology processes waste plastic into new building material, which can also be used as the core of flood embankments.

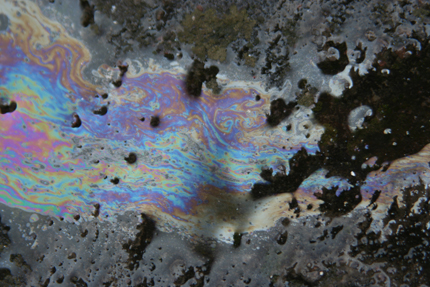

“Oil” contaminated soil remediation is a process used to remove oil stains and contaminants from soil and groundwater. We implement the method of cleaning, including mechanical removal, bioremediation and physical methods.

Petroleum is a type of hydrocarbon that consists of different types of hydrocarbons such as alkanes, aromatics and petroleum polysulfides. These hydrocarbons can be refined and separated into different fractions that are used to produce various products such as gasoline, diesel fuel, kerosene and lubricants.

The implementation method is chosen after a site visit, chemical analysis of the waste soil, the desired level of cleaning and needs

"Oil" contaminated soil remediation

Solving the problem of waste from industry and energy

With experience in the field of environmental engineering, efficient management of resources, we ensure to the maximum extent possible for our clients that the production residue in their production process meets the conditions for by-products, which are therefore not waste.

With the realization of the above, especially in the branch of industry and energy, priority consideration of the EU waste management hierarchy can be achieved to the greatest extent possible – prevention of waste generation, waste management costs are reduced, with the production of new materials from by-products (which meets technical and environmental requirements depending on the purpose of their use), natural resources are preserved, and all of them ultimately have a significant impact on reducing the costs of their production and achieving higher added value and economic growth, while respecting all environmental regulations and strategies.

Textile waste is processed into insulating material for insulating buildings. This is done using a mechanical-chemical method.

The mechanical method involves the mechanical separation of fibers from textile waste and their transformation into insulating material.

The chemical method, on the other hand, involves the use of chemicals to break down textile waste and transform it into insulating material.

Processing of textile waste

processing of concrete and brick

The processing of concrete and brick construction waste is carried out by physical and chemical processes.

Physical processes include mechanical crushing, chipping and refining, while chemical processes involve the use of reagents to break down the cement bonds.

After processing, concrete and bricks are used as building materials for new projects and products.

The processing and cleaning of soil contaminated with heavy metals is carried out using different methods, depending on the level of contamination and the type of heavy metals.

Some methods include physical removal, such as mechanical removal, water removal, and vacuum removal. Chemical methods include the use of reagents to degrade heavy metals and bioremediation, where we use microorganisms to degrade heavy metals.

Processing and cleaning of soil contaminated with heavy metals

Life Cycle Analysis & AI

The integration of Artificial Intelligence into the waste processing process in the LCA method using artificial intelligence (AI) in the waste processing process has been piloted at the end of 2022, as it can help improve the efficiency of the entire processing process. We use AI to analyze data about waste, such as type, amount in composition, and based on this, it can make decisions about how best to process the waste. We also use AI to automate processes with the goal of higher quality end products.

Life cycle analysis (LCA) is a method used to assess the environmental impacts of a product or process throughout its life cycle. We use it to assess the reduction of CO2 emissions in the waste processing process by examining the carbon footprint of the process, including emissions from transport, waste processing and energy used.

We use the LCA results for certification purposes in proving greenhouse emissions compared to other possible technologies!

INNOVATIVE BUSINESS MODEL

Luxverte technologies® represent innovatively, technological solutions for major ecological problems and it is founded and owned by Praimgest company, based in Luxembourg.

Waste plastic is one of the major ecological problem of modern society, so it is important that we always find new and better ways of material processing, possibly mass recycling into new products.

Our technology processes waste plastic into new building material, which can also be used as the core of flood embankments.

Life Cycle Analysis & AI

The integration of Artificial Intelligence into the waste processing process in the LCA method using artificial intelligence (AI) in the waste processing process has been piloted at the end of 2022, as it can help improve the efficiency of the entire processing process. We use AI to analyze data about waste, such as type, amount in composition, and based on this, it can make decisions about how best to process the waste. We also use AI to automate processes with the goal of higher quality end products.

Life cycle analysis (LCA) is a method used to assess the environmental impacts of a product or process throughout its life cycle. We use it to assess the reduction of CO2 emissions in the waste processing process by examining the carbon footprint of the process, including emissions from transport, waste processing and energy used.

We use the LCA results for certification purposes in proving greenhouse emissions compared to other possible technologies!

protected trademark by

PRAIMGEST S.A

68 AVENUE DE LA LIBERTE, 1930 LUXEMBOURG

+352 2785 8907

+352 6612 557 26

info@luxverte.lu